Temperature Control System for Semiconductor Testing /Assemblies Testing& Process Cooling Chiller

AppCAlitions

1.Stress testing for chip function and load testing, environmental simulation and in-circuit testing of electronic components.

2.In the manufacture of semiconductor electronic components for harsh environments, the testing phase of IC package assembly and engineering and production includes electronic thermal and thermal testing at temperatures (-85°C to +250°C) and other environmental test simulations.

3.Used for cooling or heating when Party A’s test bench does fuel and lubricating oil tests.

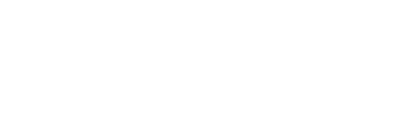

TES series is to remove the heat from the test bench through the input output of heat through the heating and cooling process of the internal thermally conductive liquid I refrigerant.

Applied PCB boards,electronic chips cooling heating test.

Adaptability of PCB Board/Electronic chip operation and storage in simulated climate and extreme environments.

working principle

The fully enclosed pipeline design reduces the demand for heat transfer fluid and improves the heat utilization rate of the system. The heat transfer medium is in a closed system with an expansion vessel, and the heat transfer medium in the expansion vessel does not participate in the circulation. High temperature cooling technology can directly cool down from a high temperature of 300 degrees.

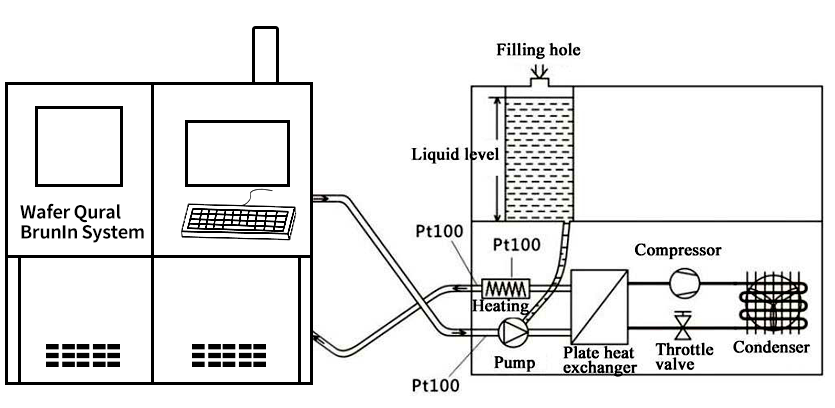

The heat transfer oil refrigeration and heating device provides low temperature or high temperature heat transfer oil. The heat transfer oil and the fuel oil exchange heat in the heat exchanger at the inlet of the test piece, so that the fuel oil can reach the desired temperature condition. The problem of pump temperature resistance also solves the problem of fuel carbonization and coking caused by excessive heater surface temperature.

Large-size color touch screen, record temperature changes in the form of curves;

The default water-cooled type, you can choose the air-cooled type, the upper air outlet design;

All compressors are of international brands with high efficiency;

The wiring of the electrical cabinet is clear and the structure is compact;

Standard size of liquid inlet and outlet, stainless steel material;

Powerful circulating pump to ensure the delivery of high viscosity liquid.

more parameters

| Model | TES-4 | TES-8 | TES-6A(Antifreeze Test) |

| Temperature Range | -45℃~250℃ | -85℃~200℃ | -60℃~200℃ |

| Heating Power | 3kW~25kW | 2.5kW~25kW | 15kW~60kW |

| Cooling Capacity | 0.3kW~25kW | 0.3kW~25kW | 3kW~60kW |

| Temperature Control Accuracy | ±0.3℃ | ±0.3℃ | ±0.3℃ |

| Circulating pump flow, pressure max | 25L~150L/min bar | 25L~150L/min bar | 110L~500L/min bar |

| Power supply 380V50HZ | 36kW max | 50kW max | 102kW max |

Note: Please leave your detailed requirements, we will select or customize products for you.

Video Introduction

LNEYA represents the international advanced liquid temperature control technology, actively explores and studies component testing systems, mainly used for temperature test simulation in semiconductor testing, with wide temperature orientation and high temperature rise and fall, temperature range -92°C ~ 250°C, suitable for various Test Requirements. LNEYA is committed to solving the problem of temperature control lag in electronic components.

Once put into practical use, these semiconductor devices and electronic products can be exposed to extreme environmental conditions to meet demanding military and telecommunications reliability standards.

Apptication Field

Temperature control of etching baths for wet chemical fabrication of wafers and microchips;

1.Component cooling, water cooling, etching baths, wet chemistry, etc.;

2.Temperature control of etching tank;

3.Electronic component material testing;

4.Keeping etch rates constant and predictable, a perfectly balanced temperature control system not only improves production results, but also increases process reliability and reduces production time, cost and maintenance.

We have extensive experience in process temperature control for the semiconductor industry. If required, we adapt the temperature control solution to your individual needs.

Other Star Products

Water Chillers

Temperature Control Range: -150°C to +50°C

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System etc..

IC Shock Test Chiller

Temperature Control Range: -120°C to +300°C

Application: Temperature shock of chips, modules, integrated circuit boards, electronic components etc..

Vehicle Test Chillers

Temperature Control Range: -40°C to +135°C

Application: Battery life test,Fuel injector, pump test bench,Airbag Test,Component testing of power modules etc..

Cooling and Heating Systems

Temperature Control Range: -120°C to +350°C

Application:High Pressure Reactor/Double-Layer Glass Reactor/Double-Layer Reactor,Microchannel Reactor,Steaming System etc..

LNEYA CHILLERS

LNEYA CHILLERS