Dynamic Temperature Control Systems丨Cooling Heating Units丨Heat Tranfser Fluid System

Applications

1.High Pressure Reactor/Double-Layer Glass Reactor/Double-Layer Reactor

2.Microchannel Reactor

3.Steaming System

4.Material Low Temperature High Temperature Aging Test;

5.Semiconductor Equipment

6.Vacuum Chamber

SUNDI Series Dynamic Temperature Control System Can Be Either Air-Cooled Chiller Or Water-Cooled Chiller. The Choice Of Air Cooling Or Water Cooling Depends On Your On-Site Process Conditions And Requirements, You Can Explain To Us At The First Time, So As To Better Choose The SUNDI Model.

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System, Laboratory, University, Research Institute, Aerospace, Automotive Industry, Semiconductor and Electrical Test, Chemical, Pharmaceutical, Petrochemical, Biochemical, Medical, Hospital, R&D Workshop, Aerospace, Biological and Other Industries.

Temperature Control Systems SUNDI

Temperature Range -60°C ~ +250°C

Cooling & Heating Capacity 60kW

Temp. Acccuracy ±0.5℃

Refrigerant R-404A/R23

Temperature Range -45°C ~ +300°C

Cooling & Heating Capacity 25kW

Temp. Acccuracy ±0.5℃

Refrigerant R-404A/R507C

System pressurized 3Bar

Temperature Range -70°C ~ +250°C

Cooling & Heating Capacity 15kW

Temp. Acccuracy ±0.5℃

Refrigerant R-404A/R23

Temperature Range -80°C ~ +250°C

Cooling & Heating Capacity 80kW

Temp. Acccuracy ±0.5℃

Refrigerant R-404A/R508B

Temperature Range -90°C ~ +250°C

Cooling & Heating Capacity 80kW

Temp. Acccuracy ±0.5℃

Refrigerant R-404A/R508B

Temperature Range -100°C ~ +100°C

Cooling & Heating Capacity 80kW

Temp. Acccuracy ±0.5℃

Refrigerant R-404A/R23/R14

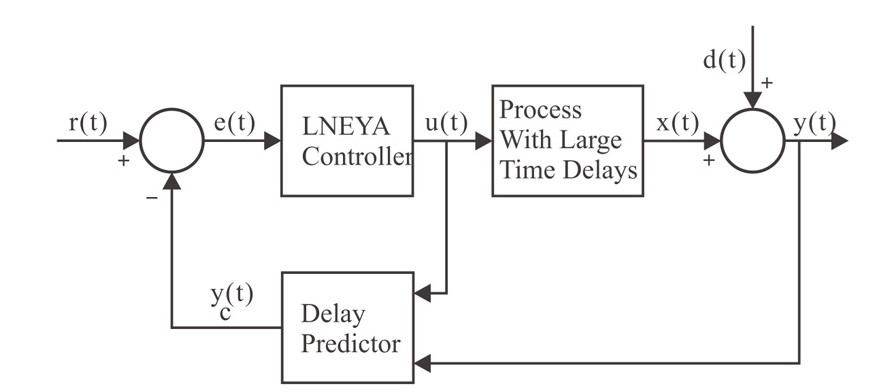

Schematic Diagram Of Cooling Heating system

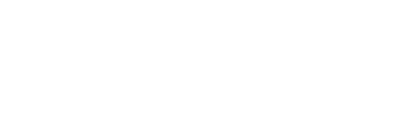

The method of changing the control setting value can respond to the system lag in the process as soon as possible and get a small system overshoot.

Through three-point sampling (material temperature point, outlet temperature of temperature control system, inlet temperature of temperature control system), through the combination of our company’s self created model free recommendation algorithm and general anti lag cascade algorithm.

SUNDI adopts fully enclosed pipeline design, high-efficiency plate heat exchanger. Reduces the need for thermal fluid utilization while providing the system with a rapid rise and fall in temperature.

The heat transfer medium is in a closed liquid circulation system with an expansion vessel, and the liquid cycle is adiabatic and does not participate in the cycle, only mechanical connection. No matter the temperature is high or low, the temperature of the expansion tank is kept at room temperature to 60 °C, which effectively reduces the risk of moisture absorption and volatilization of the heat transfer medium during operation.

Advantages of Dynamic Temperature Control system

● Working temperatures from -120°C to +350°C

● Previously unachievable performance

●Intelligent temperature control

● Maximum process stability and reproducibility

● Adop plate heat exchager, Pipeline heating, the fastest

heating and cooling rates.

● High cooling power from 0.5 to 1200kW

● Large temperature range without fluid change

● Closed system, extend thermal fluid lifetime

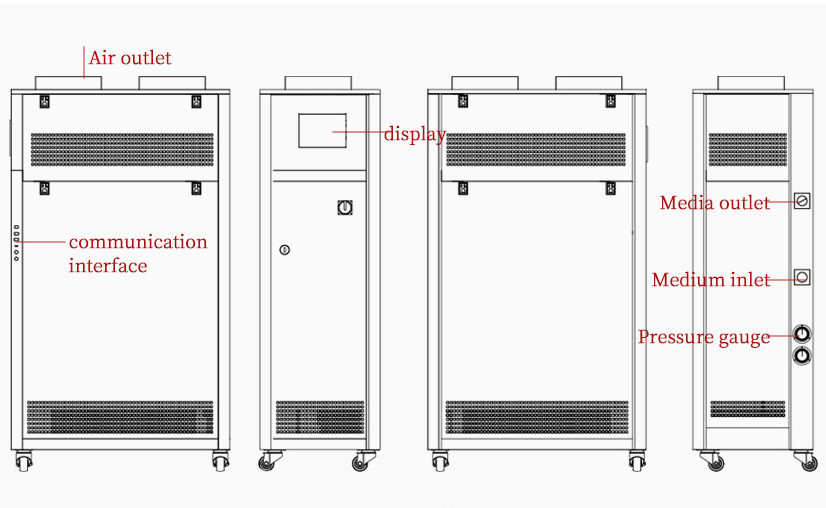

● 7-inch, 10-inch color TFT touch screen display

● Comprehensive warning and safety functions

● Rapid cooling down from high temperature (from 300 °C)

● Use magnetic drive pump, solve the circulation pump leakage

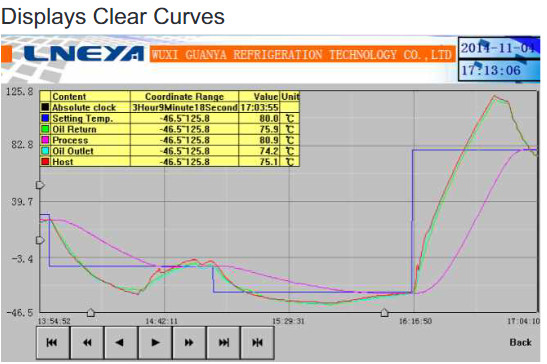

The temperature of each curve is controlled, the inlet temperature of the heat transfer oil and the temperature of the material can be independent (set the temperature difference), and the temperature difference can be controlled.

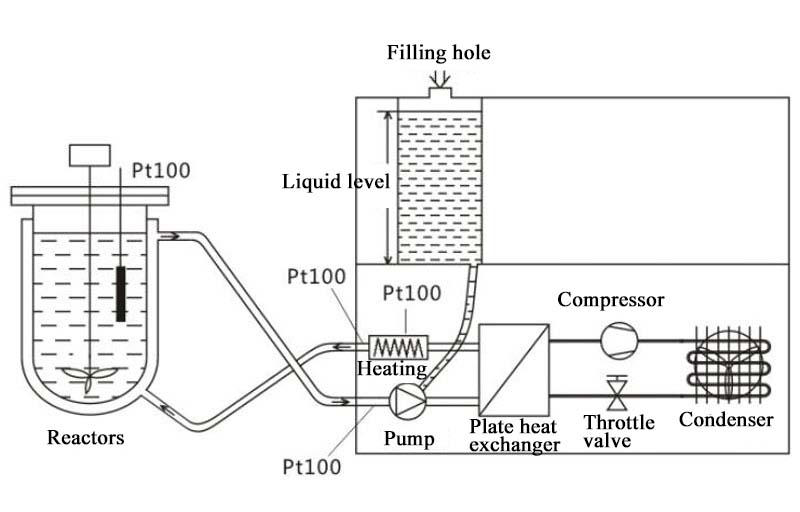

● Only the heat conduction medium in the expansion container touches the oxygen in the air. (Container temperature is limited to 60°C).

● No volatilization of the heat conducting medium at high temperature.

● No need to change the heat conducting medium. Continuous control of the temperature of the below range can be done without rising the pressure: -90°C~195°C, -70°C~220°C,-55°C~250°C, -25°C~300°C.

Heating cooling unitS Application

From laboratory benchmarks to large factories

In chemical and biological processes, the transformation of substances usually takes place in reactors, which can create consistent conditions and a safe space for the reactions. Dynamic compensation of exothermic or endothermic chemical reactions presents a greater challenge to temperature control systems. Especially if the reaction takes place in extreme temperature ranges, the temperature control system must provide fast compensation.

Therefore, a temperature control system is used that reacts highly dynamically to temperature changes inside the reactor, compensates quickly and reliably, and automatically adjusts back to the optimal range. This not only ensures efficient, consistent results, but also the safety of the process.

Viedo Introduction

Circulation Pump

High temperature resistant low temperature magnetic drive pump or a leak-free high and low temperatureshield-driven pump, reduce the risk of system leakage. At the same time the system has the advantages of lowinoise and big traffic flow.

In comparison to other thermal control systems, Dynamic Temperature Control Systems differ considerably in theirthermo dynamic characteristics. In practice Dynamic Temperature Control Systems offer definite advantages in your work:noticeable shorther heating and cooling time, better stability and reproducibility through the entire process chain, greater safety for expensive glass reactors and the contained substances, together with simple and easy operation.

Other Star Products

Water Chillers

Temperature Control Range: -150°C to +50°C

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System etc..

IC Shock Test Chiller

Temperature Control Range: -120°C to +300°C

Application: Temperature shock of chips, modules, integrated circuit boards, electronic components etc..

Vehicle Test Chillers

Temperature Control Range: -40°C to +135°C

Application: Battery life test,Fuel injector, pump test bench,Airbag Test,Component testing of power modules etc..

Cooling and Heating Systems

Temperature Control Range: -120°C to +350°C

Application:High Pressure Reactor/Double-Layer Glass Reactor/Double-Layer Reactor,Microchannel Reactor,Steaming System etc..

LNEYA CHILLERS

LNEYA CHILLERS