Products and Solutions for Biotechnology

Our dynamic temperature control systems in the SUNDI series are predestined for chemical and bio-reactors, autoclaves, miniplant and pilot plants, reaction blocks, calorimeters and distillation plant. The temperature control range is -120℃~350℃.

Precise temperature control in biotechnology has a significant influence on the production output or the results of the research.In many research laboratories and production plants LNEYA temperature control machines ensure exact temperatures and stable, reproducible process conditions. We specially recommend the SUNDI circulating heat exchangers for connection to existing cooling water/media for cooling of fermenters and bioreactors.

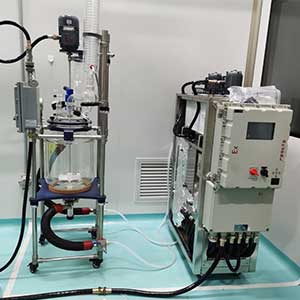

Glass Reactors

Racketed glass reactors are a common tool. The ability to control the temperature of the reaction mass depends on the speed at which the jacket’s temperature can be changed to transfer thermal energy through the glass wall.

Glass Lined Reactors

The metal component of the reactor will have a different expansion coefficient to the glass lining. To protect against stripping the glass by heating or cooling too quickly, the ramp rate can be set and controlled to either change the temperature of the jacket at a rate that does not endanger the glass lining or to be programmed in steps so that a “dwell” time allows the glass and metal to settle at the same temperature before the next change in temperature.

Continuous Flow Reactors

Flow reactors are becoming more common in research and production. LNEYA units from the simple up to large WTD are used on this application. Some of these reactors have a high flow resistance. WTD provide sufficient pressure to ensure maximum heat transfer flow for the best possible temperature control in the reaction zones within the Flow reactor.

Pressure Reactors

SUNDI are capable of extremely rapid temperature changes to control (for example) the high energy reactions often carried out in Pressure Reactors (glass/metal). The T range of SUNDI are often used for high temperature reactions of this kind. Being hydraulically sealed there are no vapours from the heat transfer fluid.

Bioreactors

Often, bioreactors can only use water or water/glycol as an TES. After a process, the bioreactors need to be cleaned and sterilised “Cleaned In Place” (CIP) and “Sterilised in Place” (SIP). These routines are carried out at temperatures up to 250 °C using steam.

Rotary evaporators

LNEYA chillers have a low internal volume which means that the generated cooling power is more concentrated on the application. Instead of wasting cooling power on a massive reservoir, more applications can be attached.

Rheometers, Viscometers

To provide accurate and constant temperature control of a sample while under test, the SUNDI or a unit from the HR series are used. Compact, flexible and providing thermal stability to 0.1℃, these units can be ideal for controlling viscometer samples.

Products Cases

Typical Applitions

Reactors, Laboratory instruments, Sample preparation, Process cooling, Quality control, Material testing, Process development, Scale-up, Miniplants, Pilot plants, Kilolabs and much more, etc.

High Precision Temperature Control In Research, Development

Research & Development

LNEYA units provide stable and predictable temperature control. This performance removes an unpredictable variant from the research.

Analytical Laboratory

These labs commonly use simple chillers to remove heat from sensitive Analytical instruments.

Scale Up

The rapid response of SUNDI series make them a common feature to keep the increased energy in larger reactions under tight temperature control.

Manufacturing

Can be “low” or “high” volume batches.

Bioproduction

SUNDI series fitted with heaters provide economic and reliable temperature control on Bio Reactors from Bench scale 1-litre fermenters to 3,000-litre Production scale Bio Reactors.

Continuous Flow

SUNDI series are used to reliably and accurately control the temperature of the reaction zones within the reactor.

Quality Control

Procedure intended to ensure that raw ingredients, purchased compounds etc. a finished product under development or a finished product is within specification.

Products & Solutions

SUNDI series -45℃ ~ 300℃

High precision, intelligent temperature control. Multi-function alarm system and safety function, 7-inch, 10-inch color TFT touch screen graphic display, magnetic drive pump, no shaft seal leakage problem.

TES series -60℃ ~200℃

IC packaging assembly and engineering and production testing phases include electronic thermal testing and other environmental testing simulations at temperatures (-45°C to +250°C).

SUNDI series -70℃ ~250℃

Ultra-high Temperature Cooling Technology Can Directly Cool Down From 300℃ High Temperature.Dynamic constant temperature control of high pressure reactor cold and heat source.

SUNDI series -90℃ ~250℃

Dynamic constant temperature control of cold and heat sources of double-layer glass reactor.At high temperature, no heat conducting medium evaporates, and continuous temperature control of – 80℃ ~ 190℃, – 70℃ ~ 220℃, – 88℃ ~ 170℃, – 55℃ ~ 250℃ and – 30℃ ~ 300℃ can be realized without pressurization.

Process Thermostats

SUNDI are designed to control temperature in a wide variety of applications across all industries. They are used extensively in many departments and applications in the Pharmaceutical industry from small scale research to large scale production over a temperature range of -125 °C to 350 °C.

Their ability to rapidly change the temperature of the circulating heat transfer fluid and the advanced self-tuning PID controller provides the application with extremely tight and responsive temperature control. This can be seen in the Case Study collection on the LNEYA website.

LNEYA CHILLERS

LNEYA CHILLERS