LNEYA specializes in the production of R&D heating systems with a temperature control range of 50 to 300 degrees, which enables high temperature cooling processes, from 40 degrees directly to 50 degrees. Equipped with a heating and cooling integrated container, the heat exchange area is large, the temperature rise and fall is fast, and the heat transfer oil demand is small.

Widely used in petrochemical, chemical, pharmaceutical, biological engineering, life science, Light industry and food,Industry, sample testing and so on.

PRODUCT DESCRIPTION:

1. UST series adopts high temperature cooling process to achieve 300C~50C cooling;

2. Equipped with a heating and cooling-body container, the heat exchange area is large, the heating and cooling rates are fast, and the demand for heat transfer oil is relatively small;

3. It can realize continuous heating and cooling;

4. Circulation closed system, no oil mist volatilization at high temperature, heat transfer oil will not be oxidized and browned;

5. With the function of correcting the internal circulation temperature probe PT100;

6. The liquid circulation of the whole system is airtight, the system has an expansion vessel, the expansion vessel and the liquid circulation are adiabatic, do not participate in the liquid circulation, but are only mechanically connected, and the medium in the expansion vessel is lower than 60C;

7. The circulating water of 15’C is allowed to pass through, so that the controllable temperature range of the system can be extended to 25~300℃.

| Model | UST-3530 | UST-5530 | UST-7530 | UST-A1030 | UST-A1530 | UST-A2530 | UST-A3830 | UST-A6030 | UST-A9530 |

| Temp. range | +50℃~+300℃ |

| Control Mode | Feedback PID + Our special dynamic control calculation, PLC controller |

| Temp. control | Process temp. control and jacket temp. control model |

| Temp. difference | Set or control the temperature difference between jacket oil and raw material process |

| Program Editor | 5 programs, each program can edit 40 steps. |

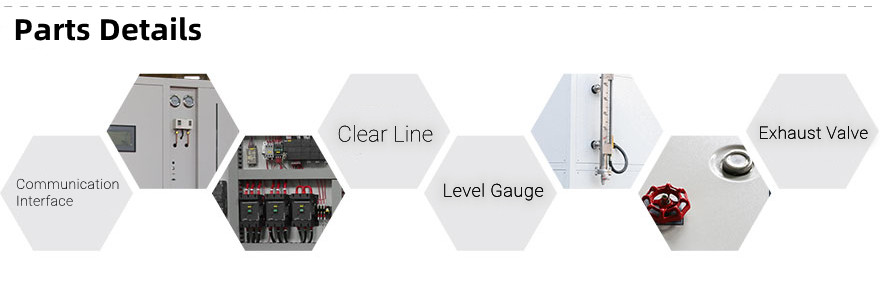

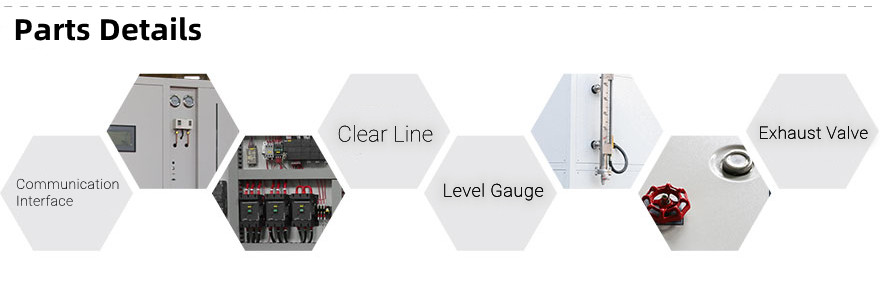

| Communication Portocol | MODBUS RTU Protocol,RS485 interface |

| Material temp. feedback | PT100 OR 4~20mA or communication(normal: PT100) |

| Temp. feedback | The temp. of three points: the inlet and outlet of equipment, reactor material temp.(external temp. sensor) |

| Medium temp. acccuracy | ±0.5℃ | ±1℃ |

| Material temp. accuracy | ±1℃ |

| Heating power kW | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 |

| Cooling capacity kW at ℃ | 300 ℃ | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 |

| 200 ℃ | 3.5 | 5.5 | 7.5 | 10 | 15 | 25 | 38 | 60 | 95 |

| 100 ℃ | 2.8 | 4 | 5 | 7 | 12 | 20 | 30 | 48 | 76 |

| 65 ℃ | 1 | 1.8 | 2.2 | 3 | 5 | 8.5 | 12 | 19 | 30 |

Circulation pump max

L/min bar | 35 | 35 | 50 | 50 | 110 | 150 | 200 | 250 | 400 |

| 2 | 2 | 2 | 2 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 |

| Connection size | ZG3/4 | ZG3/4 | ZG1 | ZG1 | ZG1 | DN32 PN10 | DN40 PN10 | DN40 PN10 | DN50 PN10 |

| Dimension cm | 40*70*130 | 40*70*130 | 45*70*160 | 45*70*160 | 70*100*175 | 70*100*175 | 80*120*185 | 150*100*185 | 205*145*205 |

| Weight kg | 95 | 110 | 120 | 160 | 195 | 265 | 395 | 615 | 1220 |

| Power 380V 50HZ | 5KW | 7KW | 9KW | 12kw | 17kw | 28kw | 41kw | 65kw | 101kw |

LNEYA CHILLERS

LNEYA CHILLERS