Water-cooled Chillers丨Ultra-low Temperature Chillers丨Cryogenic Chillers

Applications

1. A liquid low temperature cooling using heat transfer medium, used in chemical, pharmaceutical, military, aerospace, biochemical industries, low temperature, ultra-low temperature process, supporting extraction, distillation, reaction kettle… for filtration, crystallization… reactions.

2. It can cooperate with CBD equipment, CO2 extraction equipment, PVD equipment, etc. to provide low circulating temperature for the reaction process.

Chillers Instructions

The water-cooled chiller uses a shell-and-tube evaporator to exchange heat between water and refrigerant. The refrigerant system absorbs the heat in the water. After the water is cooled, the heat is transferred to the shell-and-tube condenser through the compressor. After the water absorbs heat, the heat is taken out to the external cooling tower through the water pipe for heat dissipation.

Note: Both Air Cooled Chillers And Water Cooled Chillers Are Available. Explosion Proof Cabinet Can Be Customized.

Ultra-low Temperature Chillers

Temperature Range -60°C ~ -10°C

Cooling Capacity Up to 360kW

Circulating Pump 6.6m³/h~25m³/h 2.5bar

Refrigerant R404A/R23

Temperature Range -80°C ~ -30°C

Cooling Capacity Up to 270kW

Circulating Pump 6.6m³/h~25m³/h 2.5bar

Refrigerant R404A/R23 Or RR508B

Temperature Range -110°C ~ -50°C

Cooling Capacity Up to 120kW

Circulating Pump 6.6m³/h~25m³/h 2.5bar

Refrigerant R404A/R23/R14

Temperature Range -150°C ~ -110°C

Cooling Capacity Up to 11kW

Circulating Pump 6.6m³/h~25m³/h 2.5bar

Chiller Type Direct Cooling

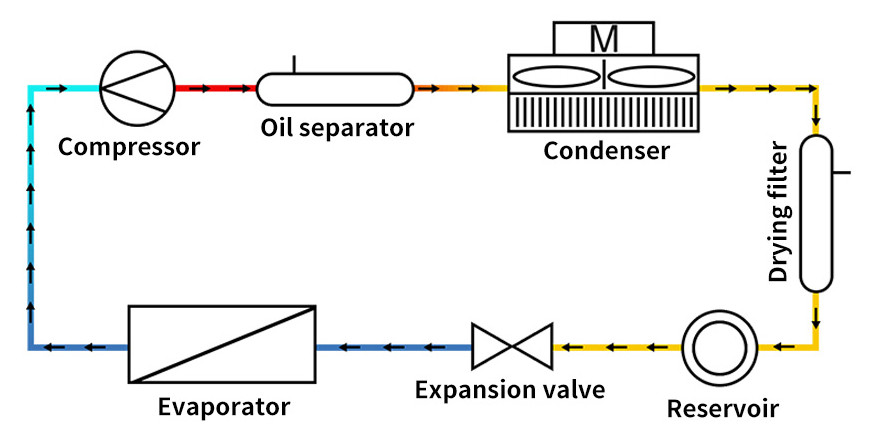

Working Principle

Single-fluid ultra-low temperature chiller, the cooling temperature range is from -150 degrees to -5 degrees, which can meet different cooling temperature needs.

The whole system is a fully closed system, and there is no water absorption during low temperature operation, which ensures the purity of the cold heat transfer medium, prevents ice crystals, and improves the life of the heat transfer fluid.

The direct-cooling ultra-low temperature freezer developed by LNEYA adopts international brand compressors and single-compressor automatic cascade refrigeration technology. It can be cooled to minus 120°C within 3 minutes, and the cooling speed is fast, safe and reliable.

Video introduction

Ultra-low Temperature Chiller Can Be Either Air-Cooled Chiller Or Water-Cooled Chiller. The Choice Of Air Cooling Or Water Cooling Depends On Your On-Site Process Conditions And Requirements, You Can Explain To Us At The First Time, So As To Better Choose Model.

Talk to us about your cryogenic cooling solution needs

Application Field

Whether decarboxylation, distillation or winterization, temperature control also plays a decisive role in the further processing of crude oil.

Perfectly balanced temperature control system not only improves production results, but also increases process reliability and reduces production time, costs and maintenance. We have extensive experience and a team of experts in the field of temperature control for industrial chemical and pharmaceutical processes. If required, we adapt the temperature control solution to your individual needs.

Advantages of Ultra-low Temperature Chillers(Water-cooled Chillers)

1.Adopt secondary subcooling technology, rapid cooling and low cooling temperature;

2.Famous brand semi-closed piston compressor, semi-closed bipolar piston compressor, semi-hermetic screw compressor, main brand are BOCK. Bitzer, Copeland, Handbell, fusheng; Plate heat exchanger, Small volume, High efficiency;

3.Top imported cold controller; Generator cooling water circuit uses intermediate heat exchanger, improve system reliability and safety.

4.DANFOSS electronic expansion valve, high precision control;

5.Adopt Siemens PLC S7-200/300, LNEYA touch screen, automatic control, temperature curve display, temperature record U disk, fault alarm;

6.Offer machine installation and system test, users only need to finish the installation of refrigerant and cooling water.

Other Star Products

Water Chillers

Temperature Control Range: -150°C to +50°C

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System etc..

IC Shock Test Chiller

Temperature Control Range: -120°C to +300°C

Application: Temperature shock of chips, modules, integrated circuit boards, electronic components etc..

Vehicle Test Chillers

Temperature Control Range: -40°C to +135°C

Application: Battery life test,Fuel injector, pump test bench,Airbag Test,Component testing of power modules etc..

Cooling and Heating Systems

Temperature Control Range: -120°C to +350°C

Application:High Pressure Reactor/Double-Layer Glass Reactor/Double-Layer Reactor,Microchannel Reactor,Steaming System etc..

Basic Structure Of Chillers

Industrial water chiller consists of compressor, condenser, evaporator, expansion valve and other accessories.

- Compressor: in the industrial water chiller system, the compressor is the power to ensure refrigeration. The compressor is used to increase the pressure of the refrigerant in the system and make the refrigerant circulate in the refrigeration system to achieve the purpose of refrigeration.

2.Condenser: high temperature and high pressure Freon of the refrigeration system enters the condenser after coming out of the compressor, releases a lot of heat to the cooling medium, and then is cooled and liquefied.

3.Evaporator: when the Freon liquid of the refrigeration system enters the expansion valve for throttling and is sent to the evaporator, it belongs to the vaporization process. At this time, it needs to absorb a lot of heat to gradually reduce the valence and mass temperature to achieve the effect of refrigeration and cooling.

4.Expansion valve: in the refrigerant system flow chart of the industrial water chiller, we found that there is a small part between the outlet of the condenser and the inlet of the evaporator, which is called thermal expansion valve. It is a throttling and depressurizing part to reduce the condensation pressure of the refrigerant to the evaporation pressure. Therefore, its role in the refrigeration system is essential. It is connected with the refrigeration compressor, evaporator, condenser It is also called the four components of the refrigeration system.

5.Other accessories: including drying filter and high and low pressure controller. The drying filter is non detachable. The internal structure adopts molecular sieve structure, which can remove a small amount of impurities and water in the pipeline, so as to purify the system. The high and low pressure controller plays a protective role in the refrigeration system.

LNEYA CHILLERS

LNEYA CHILLERS